The energy storage system is playing a more and more important role in the energy technology. The implement of this system can make energy consumption more reasonable and optimize energy utilization.

How does it work? The excess energy will be collected and stored in the system by a certain way, and it will be extracted for use during peak hours, or be transported to the areas in need.

There are 3 main parts that make up this system: energy storage reservoir, regulator and system controller.

Recently, iData has cooperated with a well-known energy storage system company to provide a digital solution for the company's production of the system controller. This cooperation has improved the management capability significantly in company's production digitization.

In order to ensure the stable operation of the entire energy storage system, the energy storage system controller is usually composed of Battery Management System (BMS), Power Conversion System (PCS), Energy Management System (EMS), thermal management system, fire protection system, monitoring system, etc. Each of them is made of circuit boards, components, chips, etc.

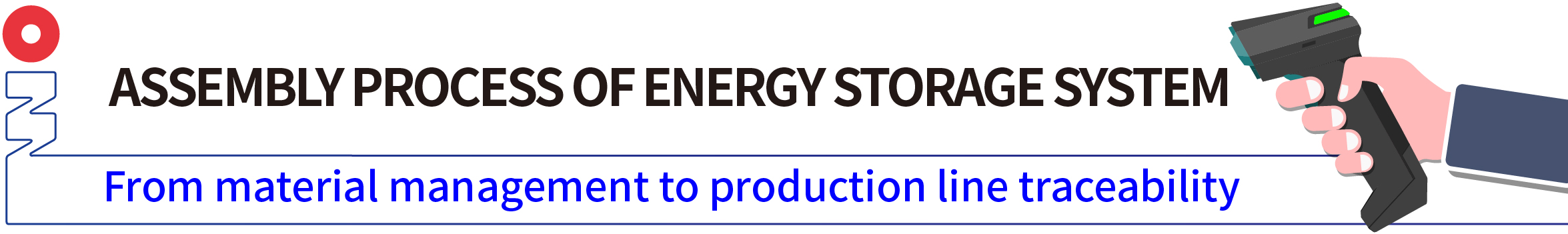

Right from the inbound process, the staff will use PDAs to record the basic warehousing information of different components, then relabel them and move them to the line-side storage, after that, the staff of the product line will assemble the components and scan codes to associate each other. In this way, the traceability of the whole process could be guaranteed.

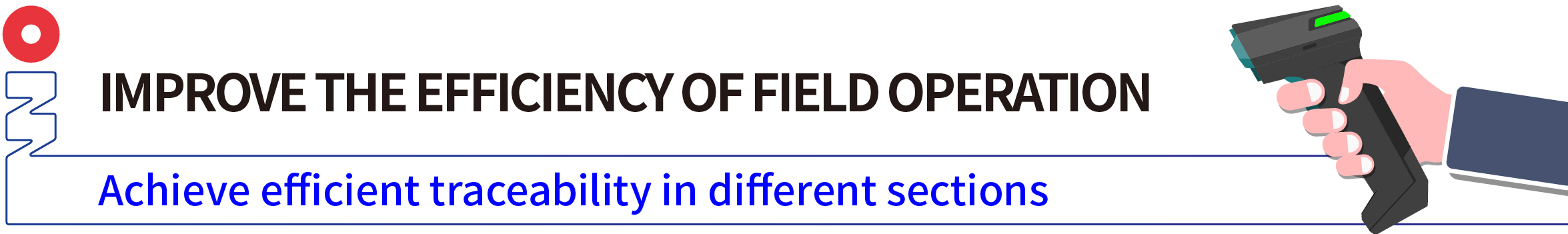

The assembly of energy storage system controllers is quite different from the assembly of traditional electronic products such as mobile phones, tablets, and computers. Due to the huge differences in the size of the assembled components, different processes will apply different working standards. For example, for those small components assembly and code scanning association, it could be done by one single staff; However, for those large ones, the assembly process and code scanning process are usually done by different staff in order to reduce components transportation.

At present, this company adopts iData 50P for inbound and outbound management for incoming materials management, and iData J16-BT for production line traceability in energy storage system assembly. iData equipment have helped improve the working efficiency of staff and the digital management capabilities of the enterprise significantly .

If you want to learn more about new energy industry applications, or try iData J16-BT, you can also get in touch with iData to get latest information.

About iData